Corrosion Mapping

Image - corrosion-mapping

- NDT Method

UT Thickness Gauging - Application Category

Corrosion Mapping

Cause & Effect

Corrosion, a common and serious problem faced by industries; particularly industries like petrochemical and power sectors that use or generate Hydrocarbons, Steam & Water in their processes. These Hydrocarbons react with plant equipments or Pipelines resulting in corrosion or erosion.

Corrosion and erosion can inflict significant damage upon petrochemical vessels and pipework. Other phenomena such as hydrogen induced cracking and high temperature hydrogen attack can also prove costly to plant operation. Due to the risks involved, it is important to recognize corrosion damage as early as possible, especially when such knowledge can assist in planning an operational maintenance strategy.

Our Solution

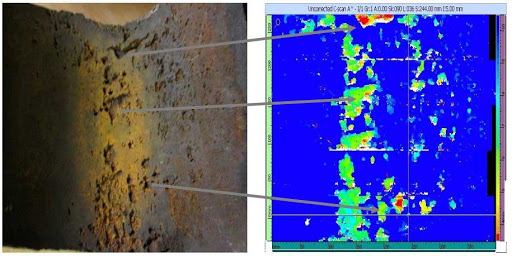

Corrosion mapping is an ultrasonic technique which maps and identifies variations in material thickness due to corrosion. Variations in material thickness due to corrosion can be identified and graphically portrayed as an image. The technique is widely used in the oil and gas industries for the in-service detection and characterization of corrosion in pipes and vessels.

Results for corrosion mapping provide a high degree of repeatability and the advantage of position and size data for every flaw which can be compared for repeat scans of the same area to track flaw growth or corrosion rates both generally and for individual pits.

We at Vibrant NDT, possess the latest available technology in the market to provide corrosion mapping solution to our clients. Our Team is well experienced in corrosion mapping on Vessels, Pipelines etc, at Refineries, Power plants and other industries.

Talk to our team and get the best solution for your corrosion monitoring needs at the most economic, reliable and fastest way.

Articles related to Corrosion Mapping

Talk to us Now !

We offer the best and most affordable NDT services in the market.